Engineering, 26.02.2020 05:25 netflixacc0107

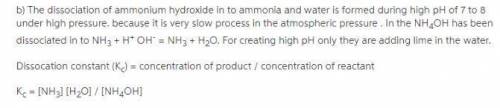

Ammonia is one of the chemical constituents of industrial waste that must be removed in a treatment plant before the waste can safely be discharged into a river or estuary. Ammonia is normally present in waste water as aqueous ammonium hydroxide (NH4OH-). A two-part process is frequently carried out to accomplish the removal. Lime (CaO) is first added to the wastewater, leading to the reaction

CaO + H2O --> Ca2+ + 2(OH-)

The hydroxide ions produced in this reaction drive the following reaction to the right, resulting in the conversion of ammonium ions to dissolved ammonia:

NH4+ + OH- <--> NH3(g) + H2O(l)

Air is then contacted with the wastewater, stripping out the ammonia.

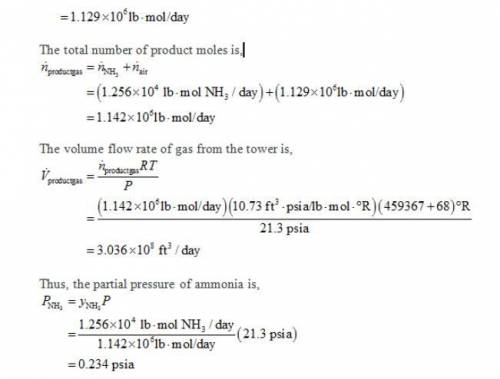

a. One million gallons per day of alkaline wastewater containing 0.03 mol NH3/mole ammonia-free H2O is fed to a stripping tower that operates at 68oF. Air at 68oF and 21.3 psi contacts the wastewater countercurrently as it passes through the tower. The feed ratio is 300 ft3 air/gal wastewater, and 93% of the ammonia is stripped from the wastewater. Calculate the volumetric flow rate of the gas leaving the tower and the partial pressure of ammonia in this gas.

b. Briefly explain in terms a first-year chemistry student could understand how this process works. Include the equilibrium constant for the second reaction in your explanation.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

Engineering, 04.07.2019 18:20

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

Engineering, 04.07.2019 18:20

How much power could a wind turbine produce if it had the following specifications? cp = 0.45 -d=1.2kg/m3 d=50m v 5m/s

Answers: 2

Engineering, 04.07.2019 19:10

What is the main objective of using reheat rankine cycle?

Answers: 3

You know the right answer?

Ammonia is one of the chemical constituents of industrial waste that must be removed in a treatment...

Questions

Mathematics, 19.02.2020 02:51

Health, 19.02.2020 02:51

English, 19.02.2020 02:51

Mathematics, 19.02.2020 02:51

Mathematics, 19.02.2020 02:51