Engineering, 18.03.2020 20:30 salmamontero1998

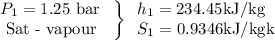

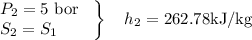

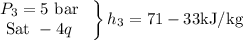

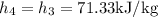

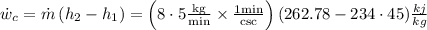

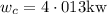

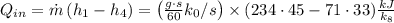

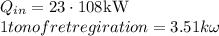

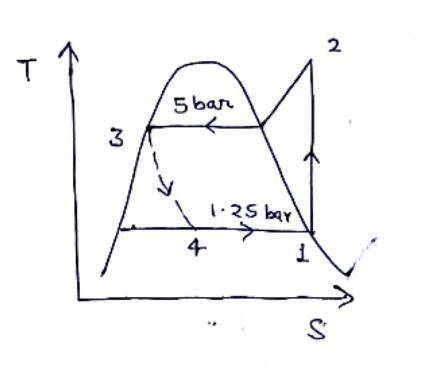

An ideal vapor-compression refrigeration cycle operates at steady state with Refrigerant 134a as the working fluid. Saturated vapor enters the compressor at 1.25 bar, and saturated liquid exits the condenser at 5 bar. The mass flow rate of refrigerant is 8.5 kg/min. Determine the magnitude of the compressor power input required, in kW (report as a positive number).

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Courses that are developed by subject matter experts, internal or extemal to the college or university. these programs are marketed by the school (clo2) marks a)-vocational schools b)-vendor training c)-colleges & universities d)-continuing education programs

Answers: 2

Engineering, 04.07.2019 19:10

Tom is having a problem with his washing machine. he notices that the machine vibrates violently at a frequency of 1500 rpm due to an unknown rotating unbalance. the machine is mounted on 4 springs each having a stiffness of 10 kn/m. tom wishes to add an undamped vibration absorber attached by a spring under the machine the machine working frequency ranges between 800 rpm to 2000 rpm and its total mass while loaded is assumed to be 80 kg a) what should be the mass of the absorber added to the machine so that the natural frequency falls outside the working range? b) after a first trial of an absorber using a mass of 35 kg, the amplitude of the oscillation was found to be 10 cm. what is the value of the rotating unbalance? c) using me-3.5 kg.m, find the optimal absorber (by minimizing its mass). what would be the amplitude of the oscillation of the absorber?

Answers: 3

Engineering, 04.07.2019 19:20

Determine the stoichiometric and actual air-fuel ratios and the mole flue gas composition for combustion with 15% excess air for raw indiana, pennsylvania raw coal.

Answers: 3

Engineering, 04.07.2019 19:20

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

You know the right answer?

An ideal vapor-compression refrigeration cycle operates at steady state with Refrigerant 134a as the...

Questions

Biology, 02.02.2021 22:50

Social Studies, 02.02.2021 22:50

English, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Biology, 02.02.2021 22:50

English, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Mathematics, 02.02.2021 22:50

Computers and Technology, 02.02.2021 22:50