Engineering, 21.03.2020 10:21 Harms

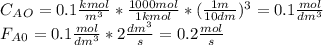

The elementary irreversible organic liquid-phase reaction A+B --> C is carried out adiabatically in a flow reactor. An equal molar feed of A and B enters at 27oC the reactor. The volumetric flow rate is 2 dm3 /s and CA0 = 0.1kmol/m3

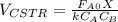

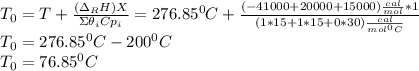

a.) Calculate the PFR and CSTR volumes necessary to achieve 85% conversion.

b.) What is the maximum inlet temperature on could have so that the boiling point of the liquid (550K) would not be exceeded even for complete conversion?

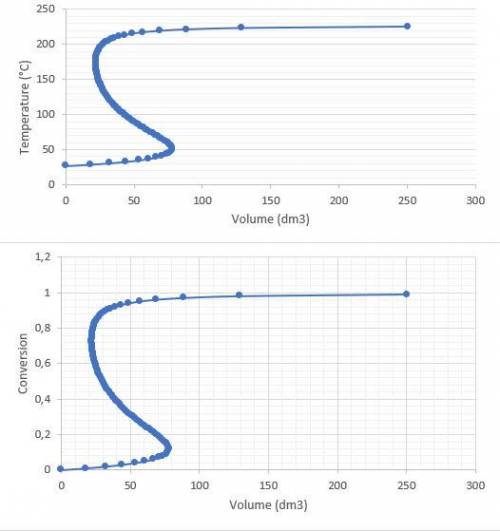

c.) Plot the conversion and temperature as a function of PFR volume (i. e., distance down the reactor)

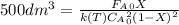

d.) Calculate the conversion that can be achieved in one 500dm3 CSTR and in two 250dm3 CSTRs in series.

Additional information:

A B C

H (273K) (kcal/mol) -20 -15 -41

Cp (cal/mol*K) 15 15 30

k=0.01 dm3 /mol. s at 300K, E=10,000 cal/mol

Answers: 1

Another question on Engineering

Engineering, 04.07.2019 18:10

The temperature of air decreases as it is compressed by an adiabatic compressor. a)- true b)- false

Answers: 2

Engineering, 04.07.2019 18:10

Water in a partially filled large tank is to be supplied to the roof top, which is 8 m above the water level in the tank, through a 2.2-cm-internal-diameter pipe by maintaining a constant air pressure of 300 kpa (gage) in the tank. if the head loss in the piping is 2 m of water, determine the discharge rate of the supply of water to the roof top in liters per second.

Answers: 3

Engineering, 04.07.2019 18:10

Awall of 0.5m thickness is to be constructed from a material which has average thermal conductivity of 1.4 w/mk. the wall is to be insulated with a material having an average thermal conductivity of 0.35 w/mk so that heat loss per square meter shall not exceed 1450 w. assume inner wall surface temperature of 1200°c and outer surface temperature of the insulation to be 15°c. calculate the thickness of insulation required.

Answers: 3

Engineering, 04.07.2019 18:20

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

You know the right answer?

The elementary irreversible organic liquid-phase reaction A+B --> C is carried out adiabatically...

Questions

History, 29.01.2020 21:01

Mathematics, 29.01.2020 21:01

Mathematics, 29.01.2020 21:01

History, 29.01.2020 21:01

Biology, 29.01.2020 21:01

English, 29.01.2020 21:01

History, 29.01.2020 21:01

Mathematics, 29.01.2020 21:01

Mathematics, 29.01.2020 21:01

History, 29.01.2020 21:01

Biology, 29.01.2020 21:01

Mathematics, 29.01.2020 21:01

and

and

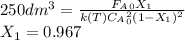

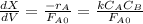

![\frac{dX}{dV}=[k_{(300K)}*exp(\frac{E}{R}(\frac{1}{300}-\frac{1}{T})]}\frac{C_AC_B}{F_A_0}](/tpl/images/0557/6585/95b8a.png)

![\frac{dX}{dV}=[k_{(300K)}*exp(\frac{E}{R}(\frac{1}{300}-\frac{1}{T})]}\frac{C_A_0^2}{F_A_0}(1-X)^2](/tpl/images/0557/6585/791bb.png)

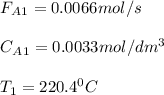

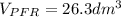

![\int\limits^{0.85}_0 {\frac{1}{(1-X)^2} } \, dX =[0.01dm^3/(mol*s)*exp(\frac{10000cal/mol}{ 1.9872cal/mol*K}(\frac{1}{300K}-\frac{1}{(197+273.15)K})]}\frac{(0.1mol/dm^3)^2}{0.2mol/s}\int\limits^V_0 {} \, dV \\\\5.667=0.216dm^{-3}V\\V=5.667/0.216dm^{-3}\\V_{PFR}=26.3dm^{3}](/tpl/images/0557/6585/b748f.png) Now, for the CSTR, just the design equation is changed by:

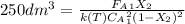

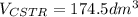

Now, for the CSTR, just the design equation is changed by:

![V_{CSTR}=\frac{0.2mol/s*0.85}{[0.01dm^3/(mol*s)*exp(\frac{10000cal/mol}{ 1.9872cal/mol*K}(\frac{1}{300K}-\frac{1}{(197+273.15)K})]*(0.1mol/dm^3)^2(1-0.85)^2} \\V_{CSTR}=\frac{0.17mol/s}{4.33dm^3/(mol*s)*0.01mol^2/dm^6(0.0225)} \\V_{CSTR}=174.5dm^3](/tpl/images/0557/6585/090b3.png)

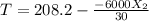

![k(T)=[0.01dm^3/(mol*s)*exp(\frac{10000cal/mol}{1.9872cal/mol*K}(\frac{1}{300K}-\frac{1}{(T+273.15)K})]](/tpl/images/0557/6585/8e617.png)