Engineering, 08.04.2020 03:11 yazmine912

To calculate the maximum allowable stresses in pressure vessels, compute the minimum allowable thickness of pressure vessels to meet certain constraints, and observe and compare properties of different pressure vessel shapes.

Engineers are considering two possible vessel shapes for storing fuel. One shape is cylindrical and the other is spherical. Each vessel would be constructed out of the same material such that its hoop stresses and longitudinal stresses would be no greater than 20.0 ksi . The cylindrical pressure vessel has an inside diameter of dc = 29.0 in and a thickness of tc = 0.500 in . The spherical pressure vessel has an inside diameter of ds = 27.0 in and a thickness of ts = 0.250 in .

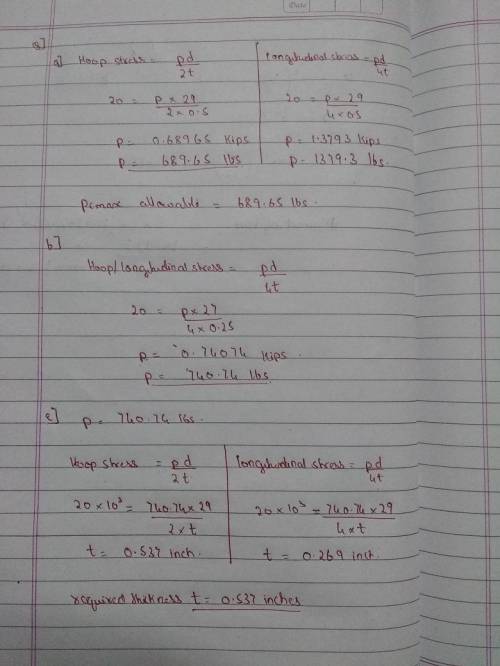

A: Determine the maximum allowable pressure, pc, max, in the cylindrical pressure vessel.

B: Determine the maximum allowable pressure, ps, max, in the spherical pressure vessel.

C: Determine the required thickness of the cylindrical pressure vessel, tr, if it is subjected to the maximum allowable pressure of the spherical pressure vessel that was calculated in Part B.

Answers: 3

Another question on Engineering

Engineering, 03.07.2019 15:10

Two flowing streams of argon gas are adiabatically mixed to form a single flow/stream. one stream is 1.5 kg/s at 400 kpa and 200 c while the second stream is 2kg/s at 500 kpa and 100 ? . it is stated that the exit state of the mixed single flow of argon gas is 150 c and 300 kpa. assuming there is no work output or input during the mixing process, does this process violate either the first or the second law or both? explain and state all your assumptions.

Answers: 1

Engineering, 04.07.2019 18:10

Aflywheel accelerates for 5 seconds at 2 rad/s2 from a speed of 20 rpm. determine the total number of revolutions of the flywheel during the period of its acceleration. a.5.65 b.8.43 c. 723 d.6.86

Answers: 2

Engineering, 04.07.2019 18:10

You are making beer. the first step is filling the glass carboy with the liquid wort. the internal diameter of the carboy is 15 in., and you wish to fill it up to a depth of 2 ft. if your wort is drawn from the kettle using a siphon process that flows at 3 gpm, how long will it take to fill?

Answers: 1

Engineering, 04.07.2019 18:10

Calculate the bore of a cylinder that has a stroke of 18 inches and an extension time of 6 seconds at a flow rate of 4 gal/min.

Answers: 3

You know the right answer?

To calculate the maximum allowable stresses in pressure vessels, compute the minimum allowable thick...

Questions

History, 11.10.2020 17:01

History, 11.10.2020 17:01

Health, 11.10.2020 17:01

History, 11.10.2020 17:01

English, 11.10.2020 17:01

History, 11.10.2020 17:01

Mathematics, 11.10.2020 17:01

English, 11.10.2020 17:01

German, 11.10.2020 17:01

History, 11.10.2020 17:01