Engineering, 14.04.2020 19:31 finnthedino

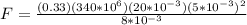

A sheet-metal part that is 5.0 mm thick, 85 mm long, and 20 mm wide is bent in a wiping die to an included angle of 90o and a bend radius of 7.5 mm. The bend is made in the middle of the 85 mm length, so that the bend axis is 20 mm long. The metal has a yield strength of 220 MPa and a tensile strength of 340 MPa. Compute the force required to bend the part, given that the die opening dimension

Answers: 1

Another question on Engineering

Engineering, 03.07.2019 15:10

If you were designing a bumper for a car, would you prefer it to exhibit elastic or plastic deformation? why? consider the functions of a bumper in both a minor "fender-bender" and a major collision.

Answers: 1

Engineering, 04.07.2019 08:10

Which of the following is an easy way to remember the modified “x” tire rotation? a. nondrive wheels straight, cross the drive wheels b. drive wheels straight, cross the nondrive wheels c. drive wheels crossed, nondrive wheels straight d. drive wheels crossed, nondrive wheels crossed

Answers: 1

Engineering, 04.07.2019 18:10

Afull journal bearing has a journal diameter of 27 mm, with a unilateral tolerance of -0.028 mm. the bushing bore has a diameter of 27.028 mm and a unilateral tolerance of 0.04 mm. the l/d ratio is 0.5. the load is 1.3 kn and the journal runs at 1200 rev/min. if the average viscosity is 50 mpa-s, find the minimum film thickness, the power loss, and the side flow for the minimum clearance assembly.

Answers: 1

You know the right answer?

A sheet-metal part that is 5.0 mm thick, 85 mm long, and 20 mm wide is bent in a wiping die to an in...

Questions

Computers and Technology, 12.08.2020 06:01

History, 12.08.2020 06:01

Mathematics, 12.08.2020 06:01

Mathematics, 12.08.2020 06:01

History, 12.08.2020 06:01

English, 12.08.2020 06:01

Mathematics, 12.08.2020 06:01

Mathematics, 12.08.2020 06:01

Mathematics, 12.08.2020 06:01