Engineering, 22.04.2020 22:31 caitlinrosekozoxegcb

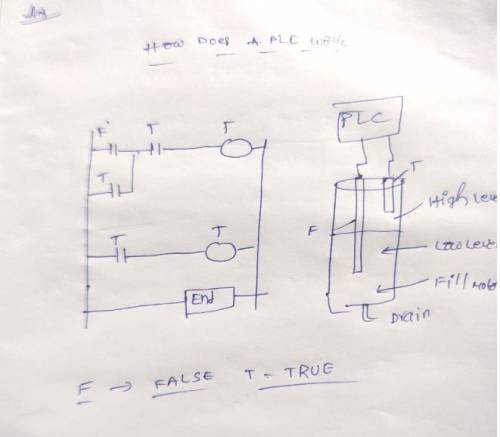

There are two ingredients (A and B) that will be mixed in the reactor tank. Wait for READY signal to be on (when on, it signifies that QA Tank is ready for this batch). 2. To add the fixed amount of ingredient A to the mixing tank, VALVE_A needs to be on. To add the fixed amount of ingredient B to the mixing tank, VALVE_B needs to be on. Both VALVE_A and VALVE_B will be turned on for 10 seconds, then they need to be turned off automatically. 3. When material A is ready to be added, PULSE_A will be on. When material B is ready to be added, PULSE_B will be on. If the PULSE_A for material A (or PULSE_B for material B) is off, the material A cannot be added to the mixing tank even the VALVE_A is turned on. 4. After the materials are fed into the mixing tank, agitate and mix the materials at a high speed (500 rpm) by turning on the motor AGIT_ON_HS for 20 seconds. 5. After that, the agitate motor is then switch for a lower speed (200 rpm) by turning on the motor AGIT_ON_LS for 30 seconds.

Answers: 2

Another question on Engineering

Engineering, 03.07.2019 14:10

Line joining liquid phase with liquid and solid phase mixture is known as: a) liquidus b) solidus c) tie line d) none of the mentioned

Answers: 2

Engineering, 04.07.2019 18:10

Water at 70°f and streams enter the mixing chamber at the same mass flow rate, determine the temperature and the quality of the exiting stream. 0 psia is heated in a chamber by mixing it with saturated water vapor at 20 psia. if both streams enters the mixing chamber at the same mass flow rate, determine the temperature and the quality of the existing system.

Answers: 2

Engineering, 04.07.2019 18:10

Water in a partially filled large tank is to be supplied to the roof top, which is 8 m above the water level in the tank, through a 2.2-cm-internal-diameter pipe by maintaining a constant air pressure of 300 kpa (gage) in the tank. if the head loss in the piping is 2 m of water, determine the discharge rate of the supply of water to the roof top in liters per second.

Answers: 3

Engineering, 04.07.2019 18:10

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

You know the right answer?

There are two ingredients (A and B) that will be mixed in the reactor tank. Wait for READY signal to...

Questions

Mathematics, 19.05.2020 16:01

Mathematics, 19.05.2020 16:01

Mathematics, 19.05.2020 16:01

Health, 19.05.2020 16:01

Geography, 19.05.2020 16:01

Mathematics, 19.05.2020 16:01

Biology, 19.05.2020 16:01

Mathematics, 19.05.2020 16:01

Mathematics, 19.05.2020 16:01