Engineering, 19.03.2020 02:47 plb2007

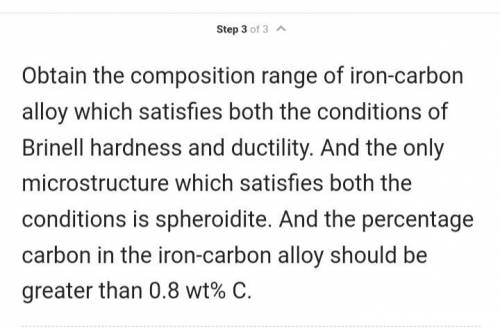

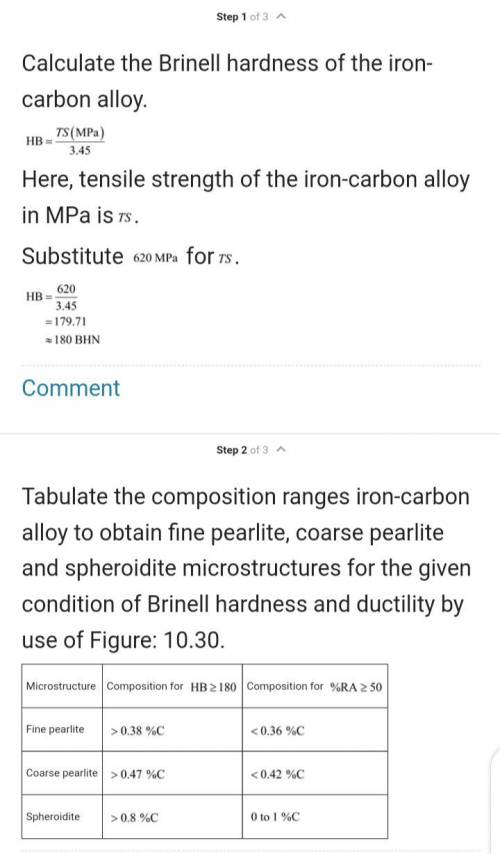

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000 psi) and a minimum ductility of 50% RA? If so, what will be its composition and microstructure (coarse and fine pearlites and spheroidite are alternatives)? If this is not possible, explain why.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

During a steady flow process, the change of energy with respect to time is zero. a)- true b)- false

Answers: 2

Engineering, 04.07.2019 18:10

The higher the astm grain-size number, the coarser the grain is. a)-true b)-false

Answers: 3

Engineering, 04.07.2019 18:10

Slip occurs via two partial dislocations because of (a) the shorter path of the partial dislocation lines; (b) the lower energy state through partial dislocations; (c) the charge balance.

Answers: 1

Engineering, 04.07.2019 19:20

Acircular pipe of 30mm outside diameter is placed in an airstream at 30 c and latm pressure. the air moves in cross flow over the pipe at 20 m/s, while the outer surface of the pipe is maintained at 110 c. what is the drag force exerted on the pipe per unit length? what is the rate of heat transfer from the pipe per unit length?

Answers: 1

You know the right answer?

S it possible to produce an iron–carbon alloy that has a minimum tensile strength of 620 MPa (90,000...

Questions

Biology, 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

History, 22.12.2019 23:31

Advanced Placement (AP), 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

Chemistry, 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

History, 22.12.2019 23:31

Mathematics, 22.12.2019 23:31

Chemistry, 22.12.2019 23:31

Computers and Technology, 22.12.2019 23:31