Engineering, 05.09.2021 01:00 christopherluckey7

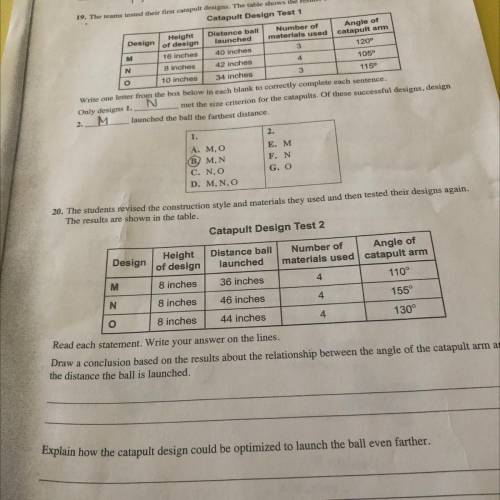

20. The students revised the construction style and materials they used and then tested their designs again

The results are shown in the table.

Catapult Design Test

Design

Height

of design

M

Distance ball Number of Angle of

launched materials used catapult arm

36 inches

4

110°

46 inches

4

155°

8 inches

8 inches

zo

8 inches

44 inches

4

130°

Read each statement. Write your answer on the lines.

Draw a conclusion based on the results about the relationship between the angle of the catapult arm and

the distance the ball is launched.

Answers: 3

Another question on Engineering

Engineering, 04.07.2019 18:10

Aflywheel accelerates for 5 seconds at 2 rad/s2 from a speed of 20 rpm. determine the total number of revolutions of the flywheel during the period of its acceleration. a.5.65 b.8.43 c. 723 d.6.86

Answers: 2

Engineering, 04.07.2019 18:10

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:20

Derive the correction factor formula for conical nozzle i=-(1+ cosa) and calculate the nozzle angle correction factor for a nozzle whose divergence hal-fangle is 13 (hint: assume that all the mass flow originates at the apex of the cone.

Answers: 3

You know the right answer?

20. The students revised the construction style and materials they used and then tested their design...

Questions

Computers and Technology, 02.03.2020 19:45

Mathematics, 02.03.2020 19:45

Physics, 02.03.2020 19:45

Mathematics, 02.03.2020 19:45